New Order Steelpaint secures 39-ship coatings deal

페이지 정보

작성자 최고관리자 댓글 0건 조회 2,084회 작성일 25-04-18 15:08본문

Steelpaint secures 39-ship coatings deal

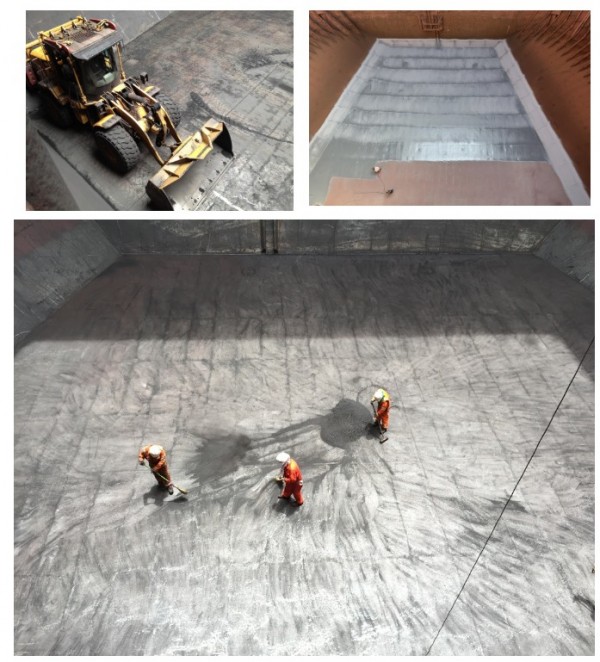

Clockwise from top left: Frequent impact from grabs and bulldozers causes significant wear to and damage to conventional coatings; A Stelpant corrosion protection system being applied to the cargo hold of a bulk carrier; A Stelpant coated hold after 20 months of operation

German coatings firm Steelpaint GmbH has secured a major order to supply its specialist Stelpant system for application to 20 dry bulk vessels operated by one of the world’s largest shipping companies. An additional 19 bulkers are scheduled for application next year.

The Singapore-based shipping group, which manages a fleet of large bulkers totalling 16 million dwt, has worked with SteelPaint for over a decade. After initial success on a couple of vessels, the shipowner opted to apply the coating to 39 ships as part of a broad fleet maintenance initiative focused on steel preservation, reduced downtime, and operational efficiency.

Previous applications found that Stelpant outperformed conventional coatings, which were quickly damaged following high mechanical stress, resulting in frequent steel replacement and recoating.

Independent testing and shipowner calculations estimate that the Stelpant system can extend maintenance intervals to 2.5 years between drydockings, significantly reducing the need for steel renewal.

Dmitry Gromilin, Steel paint’s Chief Technical Supervisor, said: “Compared to competing systems, trials under extreme mechanical stress showed that Stelpant retained a protective film on high-wear, high-impact areas after more than 17 months in service. For operators, this can substantially reduce steel replacement in cargo holds, saving an estimated $4.5 million in lifecycle savings per vessel.”

Vessels ranging from 70,000 to 200,000dwt will undergo coatings work at three Chinese shipyards: Youlian (Zhoushan) shipyard, Youlian (Shekou) shipyard, and Qingdao Beihai shipyard. SteelPaint Ltd (China) will supervise the application process.

Li Yinlong, General Manager of Steelpaint Ltd (China) said: “Application areas will focus primarily on tank tops and lower hopper regions, where frequent impact from grabs and bulldozers can cause significant wear and damage to conventional coatings.” It is anticipated Stelpant will also be applied to hatch coamings and inner bottom plating.

In each case, two 100m2 layers of the single component, zinc-rich polyurethane coating will be applied – between 7000m2 to 11,000m2 of paint per vessel.

The holds of six vessels have already been coated, with Steelpaint working closely with local partners and shipyards to ensure the quality of surface preparation and application processes.

Steelpaint Director Frank Müller said the order marks a “significant expansion of our partnership with this owner”.

He furthered that coatings renewal programmes of this size are indicative of a shifting industry mindset that prioritizes lifecycle efficiency and performance over initial material costs.

“With demand for dry bulk tonnage remaining strong, and drydock space at a premium, coatings that reduce time in the yard while enhancing structural longevity are becoming critical to competitive fleet management.”

Developed in the early 1980s, Stelpant is the result of decades long research into zinc-rich polyurethane coatings designed for extreme environments.

Unlike conventional epoxy systems, Stelpant combines high mechanical resilience with cathodic corrosion protection, making it especially suited for steel surfaces subject to heavy impact, abrasion, and prolonged moisture exposure. Its unique formulation allows for flexible reapplication without full system removal, enabling efficient touch-ups during regular maintenance cycles.

First adopted in heavy civil engineering projects such as sluice gates and sheet piles, Stelpant has gained growing recognition in the shipping industry over the past decade for its performance in cargo holds and ballast tanks, where conventional coatings often fail prematurely.

The bulk carriers included in the coatings order operate on major Asia-Pacific trade routes, moving iron ore and other minerals between Australia, New Zealand, and key markets in China and Southeast Asia. Four vessels have had already completed coatings work with three currently in progress.

■ Contact: Steelpaint GmbH www.steelpaint.de/en/