Business News NEW CUXHAVEN BERTHS TO BE PROTECTED FROM CORROSION WITH STEELPAINT SYS…

페이지 정보

작성자 최고관리자 댓글 0건 조회 1,191회 작성일 25-08-01 12:53본문

NEW CUXHAVEN BERTHS TO BE PROTECTED FROM CORROSION WITH STEELPAINT SYSTEM

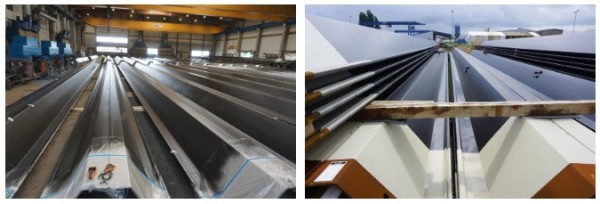

Steelpaint is supplying Stelpant directly to the steel tube and pile manufacturers and fabricators in Turkiye, and Germany. Images courtesy of Tobias Hoppe, FBK – Fachberatung Korrosionsschutz

Steelpaint’s advanced corrosion protection system, Stelpant, has been selected to safeguard steelwork at the Port of Cuxhaven, where three new berths are under construction to support Germany’s offshore wind sector.

The infrastructure project, managed by Niedersachsen Ports, will extend the quay wall by more than 1,200m to increase the port’s capacity to handle offshore wind turbine components and associated logistics.

Lower Saxony, in partnership with the federal government and local industry partners, has committed over €300 million to developments at Cuxhaven, as part of Germany’s plan to increase offshore wind capacity to 30GW by 2030.

The project will be managed by a Working Group for Cuxhaven Berths 5-7, which comprises Depenbrock Ingenieurwasserbau GmbH & Co. KG, and Tiefbau GmbH Unterweser, both located in Germany’s Oldenburg area.

Steelpaint is supplying a zinc-rich primer followed by two layers of polyurethane topcoat for the steel tubes and sheet piles that form the primary structure of the quay wall. The system is designed to withstand prolonged immersion and exposure in harsh marine environments.

Commenting on the wide scope of the project, Steelpaint director Frank Müller said: “The Cuxhaven expansion reflects the international nature of modern infrastructure projects. We are working across three countries, multiple suppliers, and adapted production processes, all within a tight timeframe. The key is not just technical performance optimisation, but coordination optimisation, as well.”

Steel tubes are being manufactured in Turkiye and imported by Hamburg-based Cremer Steel. The sheet piles are manufactured and delivered from Luxembourg. Both product types are coated prior to delivery, with an area of about 60,000m2 protected from corrosion. The system will be applied at a dry film thickness of 525µm in accordance with Germanys Federal Institute of Hydraulic Engineering (BAW).

Cremer’s Steel Division Manager, Hanno Philippi, said: “Transporting high-specification steel for a project like this demands careful coordination, but protecting it against corrosion is just as critical. Without reliable coatings, the structural longevity of marine infrastructure is compromised from the start. Our role was to ensure materials met the highest standards before reaching site.”

The coating system comprises a zinc rich moisture-cure polyurethane primer, offering cathodic protection to the steel, and two layers of moisture-cure polyurethane topcoat. Polyurethane topcoats are designed for long-term resistance to mechanical abrasion and impact, especially in submerged areas.

“The specifications demanded an elevated level of precision,” said Dmitry Gromilin, Steelpaint’s Chief Technical Supervisor.

“Only one side of each 40m tube required coating, and this side included welded clutches that had to be treated individually. This required a redesign of standard production and application method. But working directly with the steel manufacturers ensured we could meet the project’s technical and coatings’ schedule requirements.”

Knut Kokkelink, Branch Manager, Niedersachsen Ports, Cuxhaven and Stade, said: “With our extensive experience using Steelpaint systems, Stelpant proved to be a strong and reliable choice for this complex hydraulic engineering project. The international coordination has also been exemplary. Moving steel across borders involves more than transport. It’s about aligning documentation, coating schedules, and delivery sequences. This project shows that international cooperation, when well-managed, can meet the most demanding requirements.”

Steelpaint is supplying Stelpant directly to the steel producers and fabricators in Turkiye, and Germany, and has worked closely with applicators throughout the project.

Installation of the coated steel is scheduled to begin in mid-2025, with installation or “ramming in” of the components into the seabed taking place through the second half of the year. Once in place, the steelwork will provide the foundation for new berths designed to accommodate heavy-lift vessels and components for offshore wind projects.

Completion of the berths is expected in 2028.

■ Contact: Steelpaint GmbH www.steelpaint.de/en/